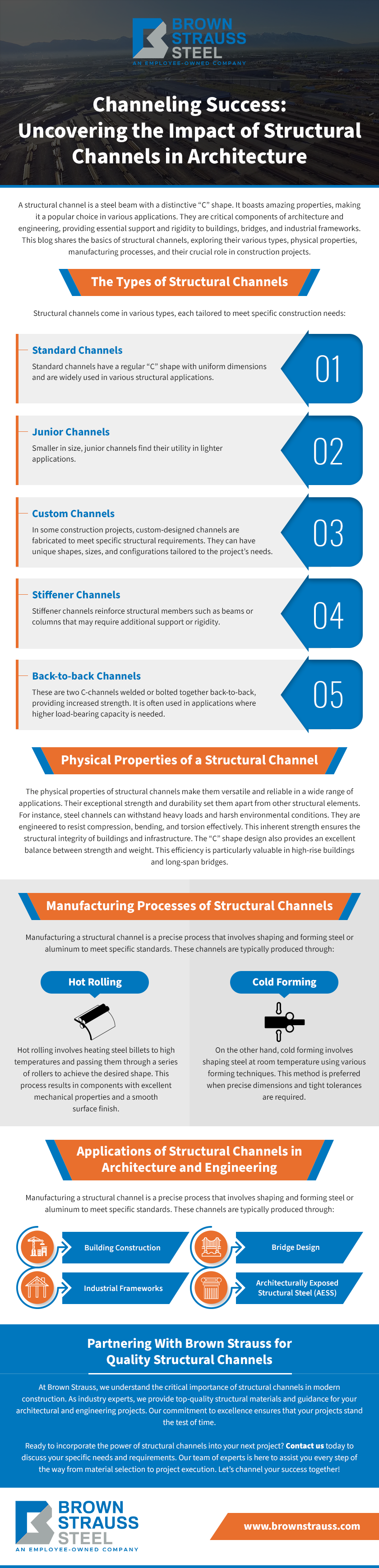

Channeling Success: Uncovering the Impact of Structural Channels in Architecture

A structural channel is a steel beam with a distinctive “C” shape. It boasts amazing properties, making it a popular choice in various applications. They are critical components of architecture and engineering, providing essential support and rigidity to buildings, bridges, and industrial frameworks.

This blog shares the basics of structural channels, exploring their various types, physical properties, manufacturing processes, and their crucial role in construction projects.

The Types of Structural Channels

Structural channels come in various types, each tailored to meet specific construction needs:

- Standard channels: Standard channels have a regular “C” shape with uniform dimensions and are widely used in various structural applications.

- Junior channels: Smaller in size, junior channels find their utility in lighter applications.

- Custom channels: In some construction projects, custom-designed channels are fabricated to meet specific structural requirements. They can have unique shapes, sizes, and configurations tailored to the project’s needs.

- Stiffener channels: Stiffener channels reinforce structural members such as beams or columns that may require additional support or rigidity.

- Back-to-back channels: These are two C-channels welded or bolted together back-to-back, providing increased strength. It is often used in applications where higher load-bearing capacity is needed.

Physical Properties of a Structural Channel

The physical properties of structural channels make them versatile and reliable in a wide range of applications. Their exceptional strength and durability set them apart from other structural elements. For instance, steel channels can withstand heavy loads and harsh environmental conditions. They are engineered to resist compression, bending, and torsion effectively. This inherent strength ensures the structural integrity of buildings and infrastructure. The “C” shape design also provides an excellent balance between strength and weight. This efficiency is particularly valuable in high-rise buildings and long-span bridges.

Manufacturing Processes of Structural Channels

Manufacturing a structural channel is a precise process that involves shaping and forming steel or aluminum to meet specific standards. These channels are typically produced through:

Hot Rolling

Hot rolling involves heating steel billets to high temperatures and passing them through a series of rollers to achieve the desired shape. This process results in components with excellent mechanical properties and a smooth surface finish.

Cold Forming

On the other hand, cold forming involves shaping steel at room temperature using various forming techniques. This method is preferred when precise dimensions and tight tolerances are required.

Applications of Structural Channels in Architecture and Engineering

The following are the most common uses of structural channels:

1. Building Construction

Structural channels play a vital role in supporting the framework of buildings. They provide the necessary rigidity and stability, ensuring structures can withstand external forces such as wind, earthquakes, and heavy loads. In high-rise buildings, structural channels are often used as vertical columns, supporting multiple floors.

2. Bridge Design

Bridges require robust structural support to span gaps and carry traffic loads. Structural channels are often used in bridge construction to create strong, durable support systems.

3. Industrial Frameworks

Structural channels create sturdy frameworks for factories, warehouses, and other large-scale structures in industrial settings. Their reliability is essential for maintaining safe and functional work environments. These channels are also used as support beams for heavy machinery, overhead crane, and conveyor systems.

4. Architecturally Exposed Structural Steel (AESS)

AESS is a design approach where the structural elements including channels are intentionally left exposed as part of the building’s aesthetics. This approach is favored for its modern and industrial look, showcasing the beauty and strength of structural channels in architectural designs. A very common form of AESS is in the form of stair stringers for an exposed staircase. A stair stringer is a vertical support board or structural member that runs along each side of the staircase. The two most common sizes for stair stringers are MC 10×8.4# and MC 12×10.6#.

Partnering With Brown Strauss for Quality Structural Channels

At Brown Strauss, we understand the critical importance of structural channels in modern construction. As industry experts, we provide top-quality structural materials and guidance for your architectural and engineering projects. Our commitment to excellence ensures that your projects stand the test of time.

Ready to incorporate the power of structural channels into your next project? Contact us today to discuss your specific needs and requirements. Our team of experts is here to assist you every step of the way from material selection to project execution. Let’s channel your success together!